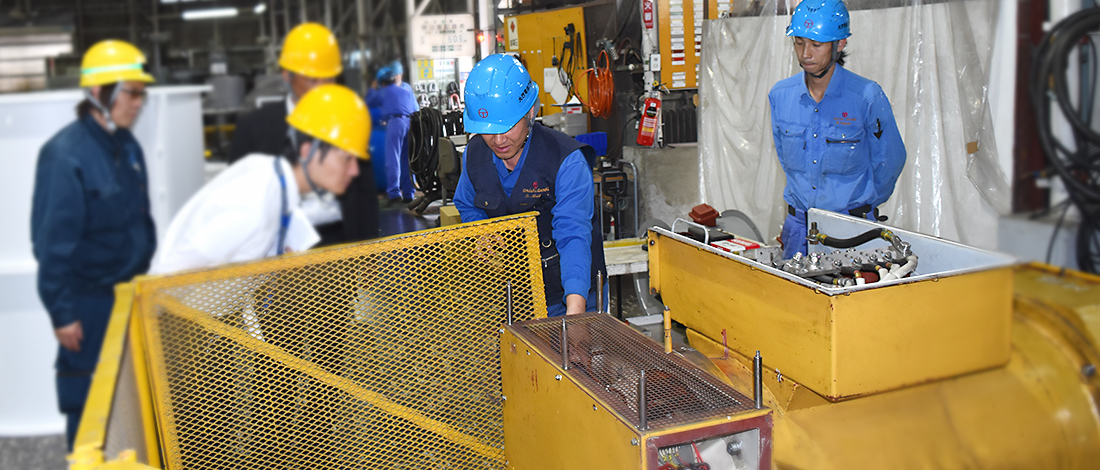

Maintenance of Generator used for vehicles

Work

It is a maintenance job of generator that is used in vehicles. After the acceptance inspection, necessary suggestions for the improvement / repair of parts to be proposed in accordance with the determination of the damage as well as the deterioration situation by the state at the time of decomposition.

Achievement track record

The result of our consultation made it clear that the failure was caused by a foreign made Generator. Giving top priorities to our customers need for the restoration of the system, we arranged the parts made by foreign countries in the shortest delivery time through our foreign business route and performed the repair work. Subsequently, we performed the environmental improvement from the adverse conditions for the high failure rate electronic components ambient temperature, such as humidity, dust, vibration etc. In addition, we proposed the replacement of parts locally to avoid long procurement time. By using our reliable domestic parts made it possible to huge cost cut and time saving for us. For this, we are trusted for all kinds of rotating parts maintenance for our speedy solutions during a sudden failure of machine.

Difficult problem and action

It is the most difficult point to apply the measures in time when the construction period is limited. In the regular maintenance it includes decomposition washing and drying, Bearing exchange, coil varnish processing drying, assembling, a trial run by the periodical maintenance. At the test examination on decomposed items for example, (the coil condition, tolerance of the bearing portion, check the winding of the coil if the breakage presence or absence, etc.). In addition we take necessary repair steps such as thermal spray, sleeve processing when we noticed a fatal damage in the coil winding and bearing. We are supporting for damaged parts and make our best efforts to arrange the manufacturer original parts as possible when we receive a parts replacement request. It takes time to arrange the original parts if the equipment made by a foreign company. We give clear idea on the intended parts and handle all these process smoothly and explain our valued customers on time.

Strengths

Our strength is the ‘improvement proposal’ by making the best use of its experience. However we don’t provide unilateral suggestions in the case of overseas product design concept as the matter not familiar to us. From our past experience we present the improvement measures and explain the fault condition and failure cause as well. According to our previous record the rotor parts of the overseas product were damaged and the terrible damage happened to the main coil. Finding no useful information from maker to distinguish the main and auxiliary coils in such a limited time we attempted to repair the coil through reading the damaged coil data and rewinding successfully. Subsequently, there was a trouble in AVR also. We proposed a power generating method and prepared design accordingly. Though the installation space was needed due to the number of parts increased, but we were able to respond to customer demand, "to minimize the failure". In this way we have to remove the root cause of the broken part in our company as well as to ensure that the same failure does not occur again. In conclusion, it is our main purpose to go ahead with quality services by giving the importance on the specialized development and improvement.

Collaboration

- ONSEC CO., LTD.

-

Role

- Planning and design

- Onishi Electric Industry Co., Ltd

-

Role

- Quality Control

- Cummins Generator Technologies

-

Role

- Purchase

- SAWAFUJI ELECTRIC CO., LTD.

-

Role

- Purchase

Project Member

-

Project leader

Hiroyuki Yamane - Maintenance work of the "rotating equipment is to maintain the performance as it was.” It seems to be easy but a very difficult task that must be performed by an expert by making the best use of its experience required. To respond any unusual things noticed at the time of decomposition, sharing information with customer and get direction related to the development. We think that the repetition of such a thing produces the relationship of mutual trust with the customer. We are committed to continue a good relationship in the future.

- Other Member

-

- Susumu Arikawa

- Ryuya Edane

- Norizumi Matsuoka