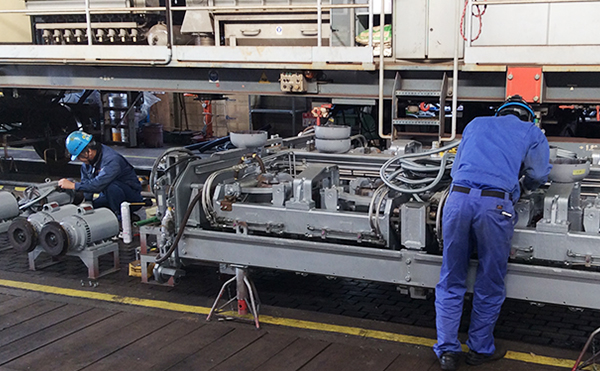

Motor maintenance on vehicle

Work details

Maintenance of vehicle electric motors, others, local removal work of rotating equipment, assembly work, disassembly inspection and maintenance work.

Achievement record

We are approaching various fields based on the technology of rotary equipment maintenance possessed by our company and responding to requests. This is the maintenance of overseas electric motors and other rotating equipment installed in maintenance vehicles. We consider some factors such as; usage environment, faulty location, frequency through disassembling the motor which appear with different specifications and propose appropriate repair solution.

Besides, maintenance of the motor main body, we also check Terminal block shape, wiring type, protective pipe etc. by judging the condition at the time of disassembling and propose suggestionsions if necessary.

Problems and initiatives

From our experience we try to collect accurate information and always struggle

From our experience we try to collect accurate information and always struggle

to adjust direction between workers and customers with optimal maintenance and operation. In this case, we asked customers about the configuration of the whole vehicle, the role of each place, the operation procedure, the operation situation at the time of work, etc. to organize the process leading to failure, propose the optimum solution.

Strength

As a group company, it is our strength to suggest the best engineering solution for the rotating equipment, and manufacturing variety of electrical device by our experienced engineering sales staff. In this case, we prepare a maintenance plan in order to ensure parts fitting accuracy, parts production from check at the time of disassembly, change of parts with good availability, etc.

As a group company, it is our strength to suggest the best engineering solution for the rotating equipment, and manufacturing variety of electrical device by our experienced engineering sales staff. In this case, we prepare a maintenance plan in order to ensure parts fitting accuracy, parts production from check at the time of disassembly, change of parts with good availability, etc.

Collaboration

- ONSEC CO., LTD.

-

Role

- Planning and design

- Onishi Electric Industry Co., Ltd

-

Role

- Quality Control

- Nomura koudensha co.,ltd

-

Role

- Assembly

- Amaden

-

Role

- Assembly

Project Member

-

Project leader

Hiroyuki Yamane - In the maintenance job sites, sometimes it become difficult to judge about the equipment because the equipment installed in maintenance vehicles found different from the equipment for general industrial use. More than 15 years of experience, we have been able to reduce the failure rate by evaluating the structure, material, repair method etc from the originals through a good connection with customers around us. Although the equipment changing always, we hope to continue working towards the optimum maintenance method in the future.

- Other Member

-

- Ryuya Edane

- Norizumi Matsuoka

- Islam Saiful