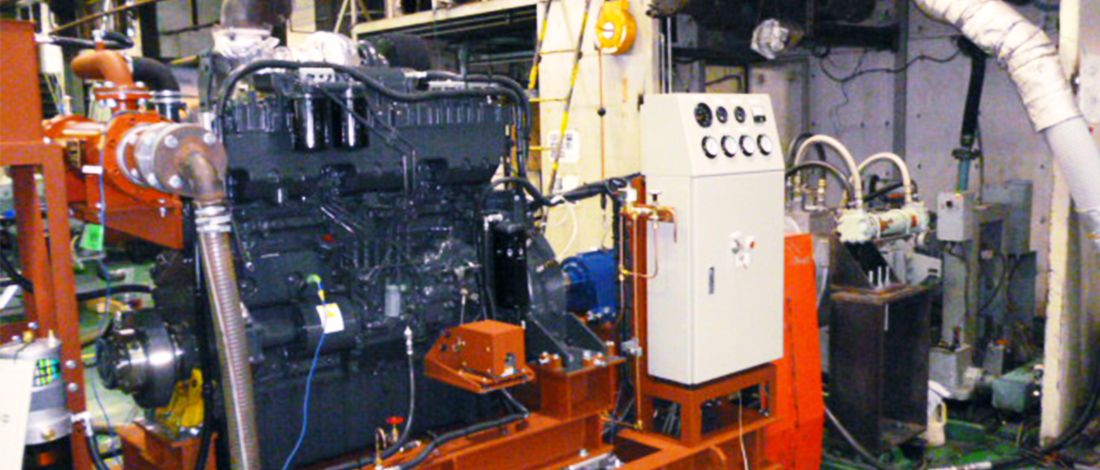

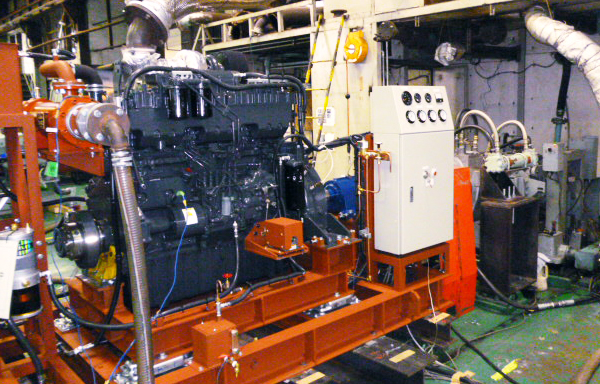

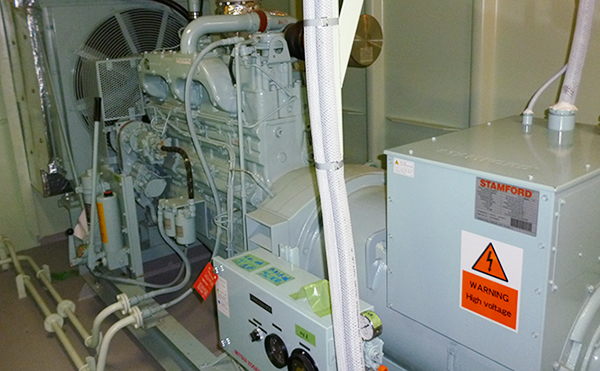

Inspection of Generator and maintenance

Work details

It is a periodical inspection and maintenance of power generation facilities. We have a wide range of maintenance items mainly generator, generator control meter boards, inspection and adjustment of engines, replacement of consumables such as engine oil, batteries, and trial operation adjustments.

Achievement record

Onishi Electric Industry a group company with the originality of marine fan manufacturing technology have been applying its experience in the maintenance and repair of electrical equipment. In engaging this type of works, the company now properly handling all types of rotating machine maintenance and repair solution. We propose the optimal solution to our valued customers through utilizing our group companies strength.

Problems and initiatives

Although there are inspection and maintenance standards, it is necessary to grasp the current situation depending on usage conditions and circumstances.

Although there are inspection and maintenance standards, it is necessary to grasp the current situation depending on usage conditions and circumstances.

As a first step, we collect information on past maintenance history etc. from customers by referring to the drawings and materials and propose equipment for necessary improvement. In this case, it was not possible to find a functional problem even after disassembling the site from engine malfunction, we repeated a resolution test afterwards and finally found malfunction in one of the fuel parts and clarified the cause. For troubles of the generator parts, when it is found a high failure rate from each measurement value and test report value, we then discuss the specifications with a proven domestic manufacturer and reach to a favorable solution.

Strength

Our strength is the flexible and responsive network gained in dealing with the rotating equipment including generators and know-how.Giving the high importance on customer's interest we try our best to get customer's acknowledgement when we face problem on the existing installation parts, non availability of old drawings, finding acquisition route when there were many discontinued parts in the replacement items in engine maintenance. In some cases, we design and manufacture control equipment from the generator data. There is also a track record of responding to customer's request that "we want to make it function as equipment" by making technical adjustments with other manufacturers.

Collaboration

- ONSEC CO., LTD.

-

Role

- Planning and design

- Onishi Electric Industry Co., Ltd

-

Role

- Quality Control

- Cummins Generator Technologies

-

Role

- Purchase

- SAWAFUJI ELECTRIC CO.,LTD.

-

Role

- Purchase

- otsuka-diesel

-

Role

- Assembly

Project Member

-

Project leader

Hiroyuki Yamane - We take pride as a group of engineers to continue support and assurance to our customers through inspection and maintenance job as requested. To that end, it is very important to improve our technical skills such as experience and know-how and build trust between our customers and partner companies. In manufacturing, it is very important to match the image to the request. We care about meeting time in advance for sharing each other's thoughts sufficiently. We will continue trying new things and making new efforts not only remaining satisfied with one completion.

- Other Member

-

- Susumu Arikawa

- Shoji Sakai